Design

Quality parts production requires an advanced R&D, production and processing line. We work in a high-level system to design, develop and produce the products the customer demands.

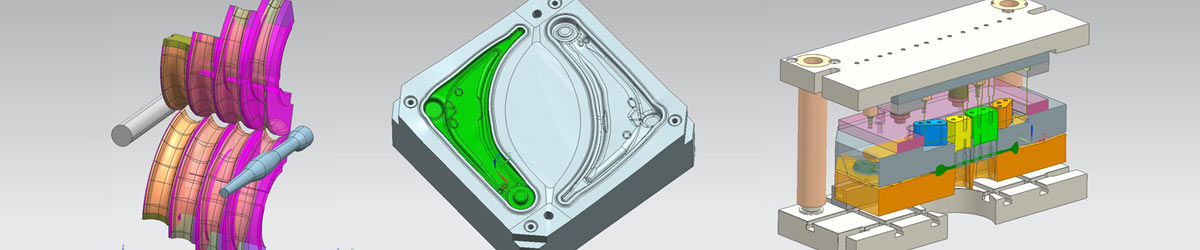

After realizing the desired products with Unigrafiks, which is the advanced parametric and mechanical design program, pre-molding process is applied with Verecad. Thanks to Verecad, the molds are designed to increase the product quality and optimize the material costs and then are 100% verified with the Simufact (FME) simulation program.

With the CAD and simulation programs, the most ideal designs are created and corrected at the first time thus providing energy and material savings also leaving room for continuous improvement. Works are conducted to determine the forces and forging problems on the mold at the design stage and appropriate solutions are produced.